Flex Laser

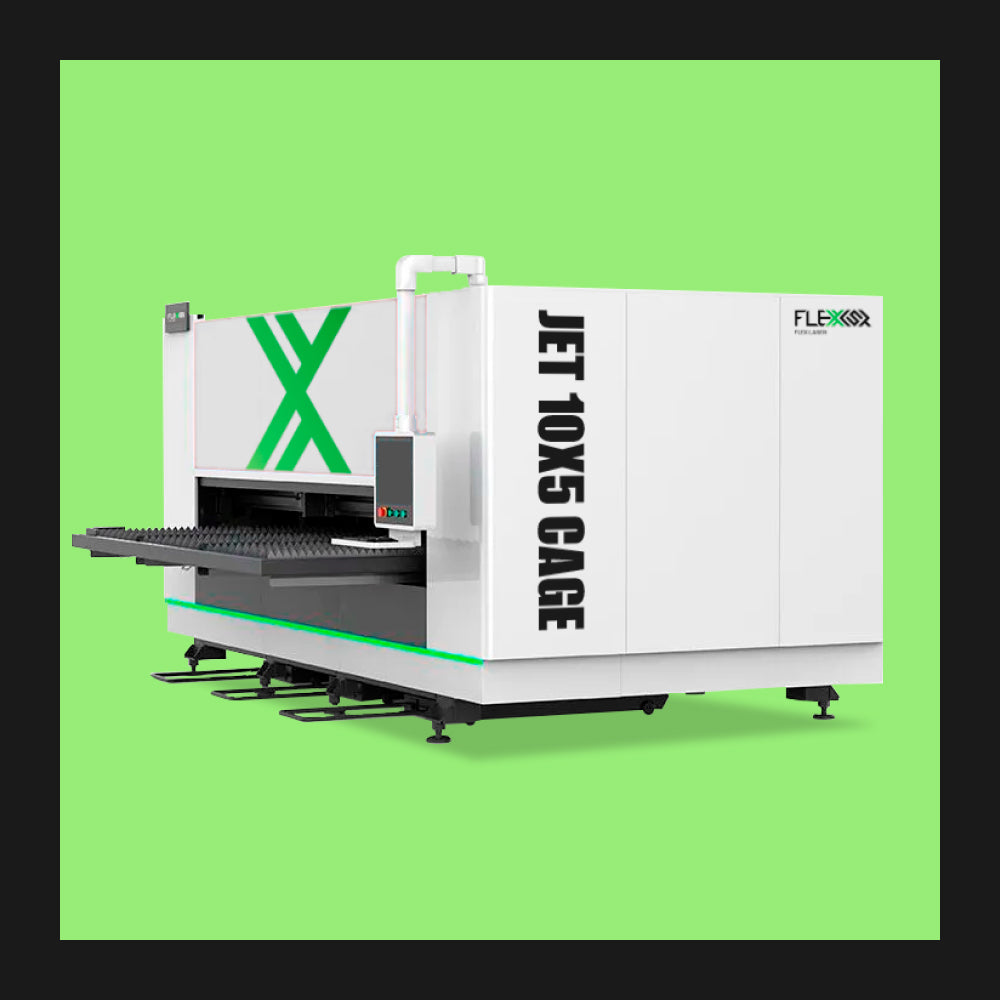

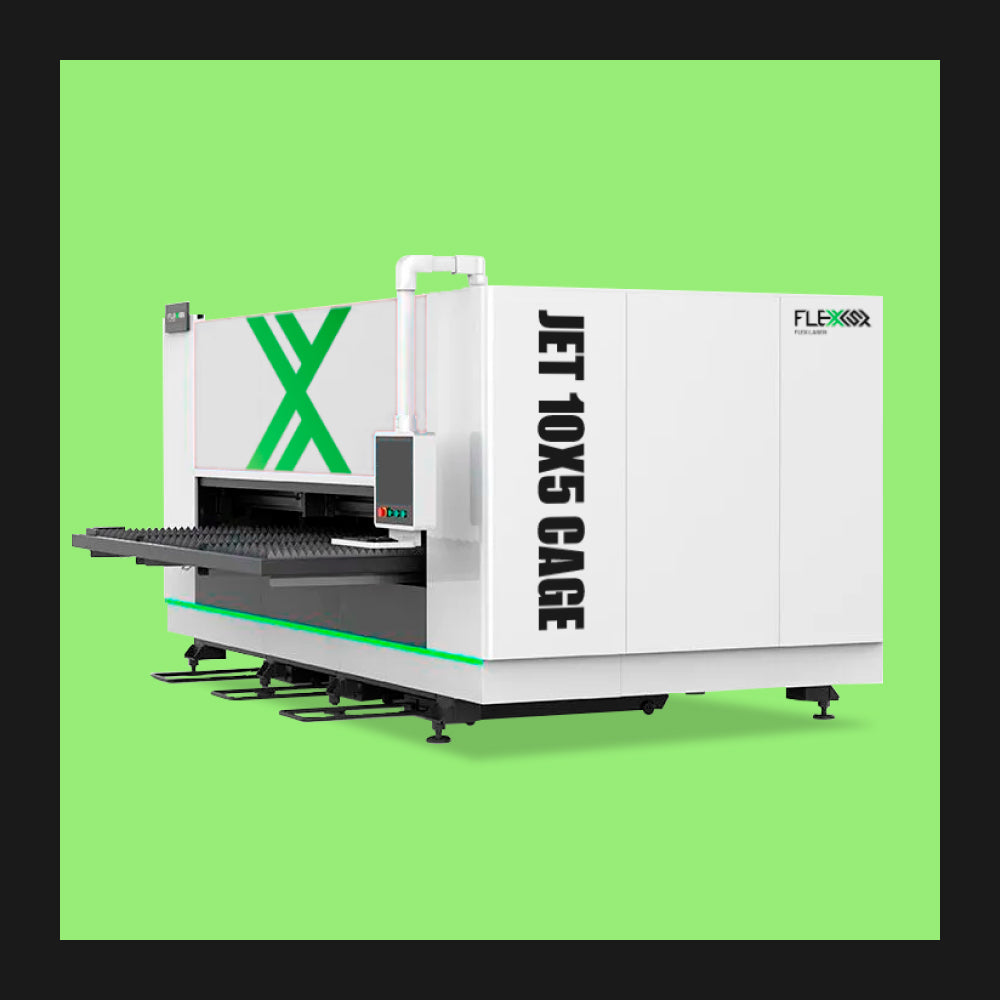

10 x 5 ft Fully Enclosure 1000w to 4000w IPG Flex Laser Fiber Metal Cutter JET10X5-CAGE

10 x 5 ft Fully Enclosure 1000w to 4000w IPG Flex Laser Fiber Metal Cutter JET10X5-CAGE

Our JET10X5-CAGE Includes:

✔ 1000w to 4000w IPG or Raycus/RECI Fiber Laser Source

✔ Compact & Fully Enclosure Design

✔ 10' x 5' ft Working Area

✔ Max. Acceleration 1.0G (1.5G Available)

✔ CypCut Professional Control Software with Nesting Function

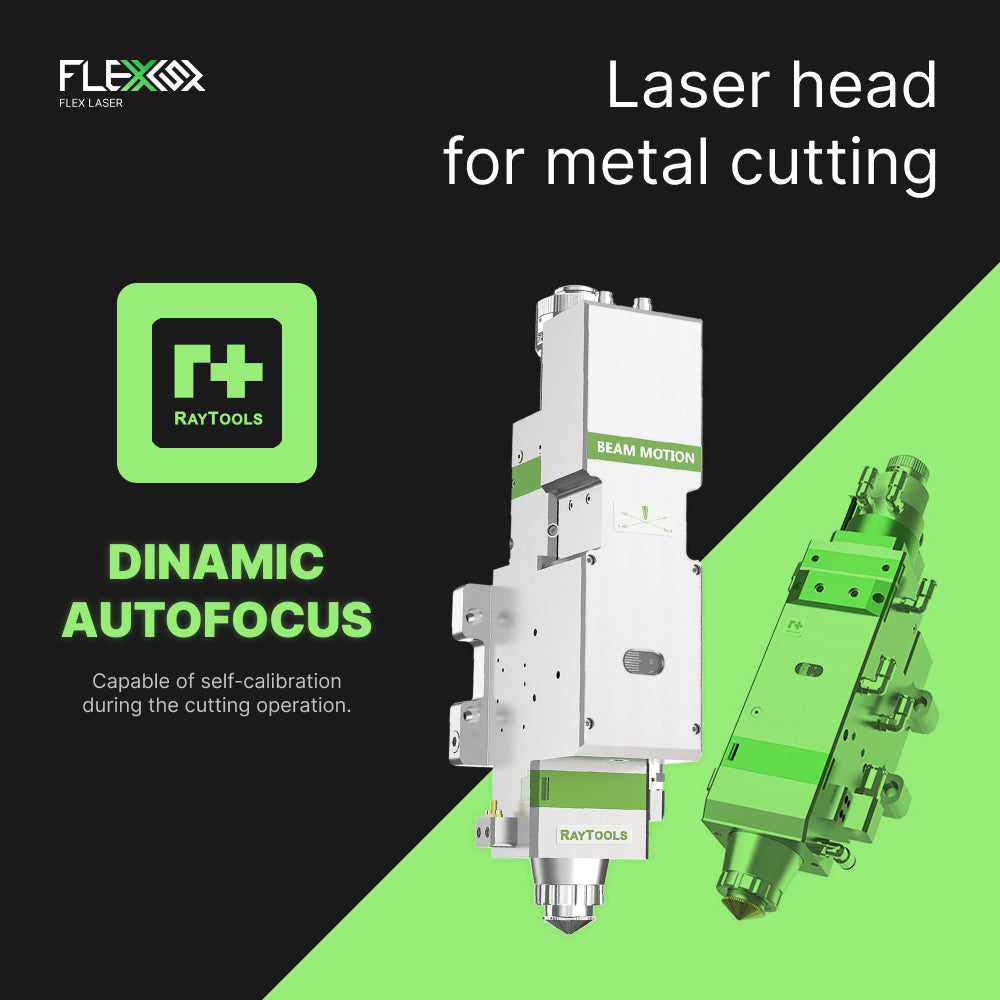

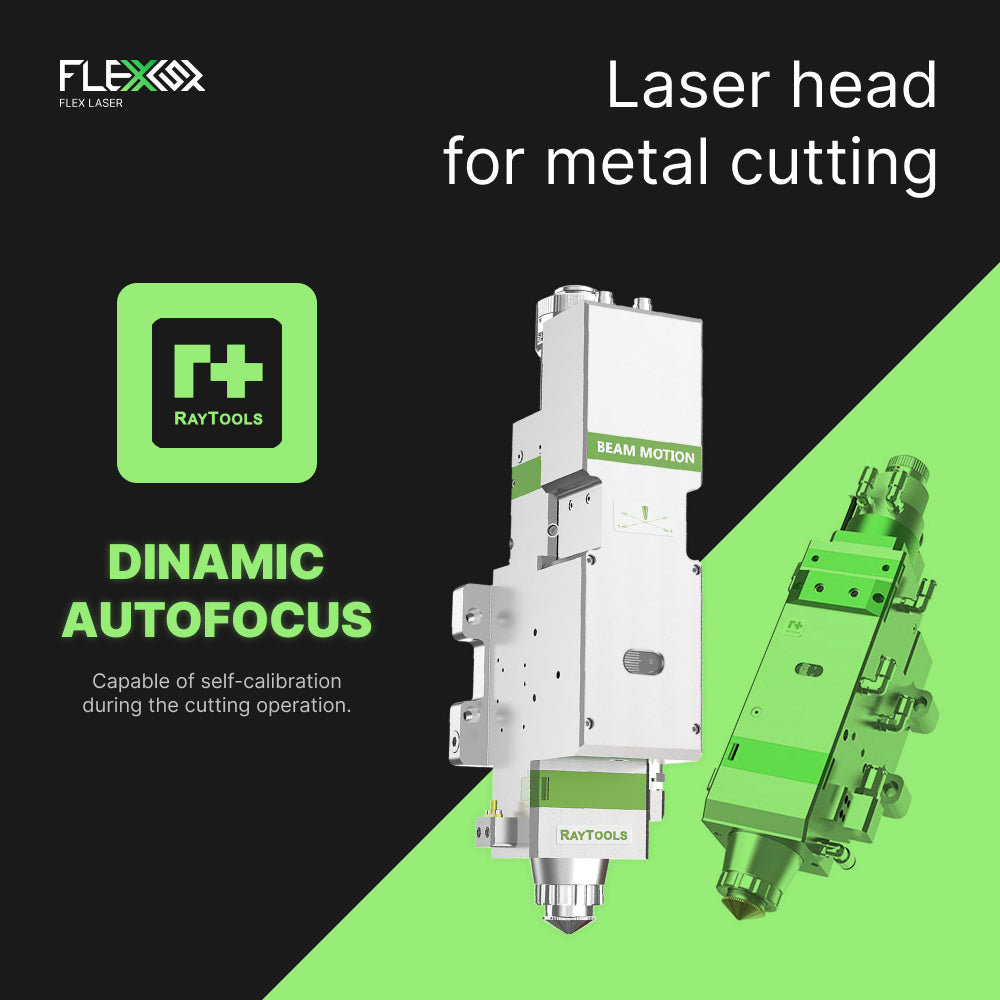

✔ Raytools Dynamic Autofocus Laser Head (Swiss Brand)

✔ Yaskawa Japanese Servo Motor System

✔ Industrial Electronic Refrigerator Chiller

✔ 2.2kw Industrial Grade Blower

✔ PC with Pre-Installed System

✔ On-Side Installation Option

Couldn't load pickup availability

Share

10 x 5 ft Fully Enclosure 1000w to 4000w IPG Flex Laser Fiber Metal Cutter JET10X5-CAGE

Collapsible content

MACHINE DESCRIPTION

FULLY ENCLOSURE FLEX LASER JET105C FIBER METAL CUTTER EQUIPPED WITH IPG OR RAYCUS/RECI 1000W TO 4000W LASER SOURCE. 10 X 5' WORKTABLE.

Description of our LASER METAL CUTTING MACHINE:

Our Enclosure CAMFive Laser Metal Cutter Model JET105C has 10x5' full sheet capacity. Is the fastest and cleanest way to cut metals like steel (stainless, mild, carbon, galvanized, mirror) Copper, brass, aluminum, and more, some of them up to 1" or 25 mm thick. It offers a stable and precise drive system with a Taiwan rack and pinion displacement axle, fast Japanese Yaskawa servo driving motors, and Raytools dynamic auto-focus.

Our lasers have been built under our CNC (Computerized Numerical Control) standards & tolerances, using strict manufacturing processes that guarantee maximum stability and minimum wear and tear of its components throughout its lifetime. Our machines can operate 24/7. It offers a stable and precise drive system with a Japanese brand displacement axle and accurate and fast step driving motors. The optical system has an American brand lens that has been optimized for outstanding performance during cutting and engraving on different materials.

DETAILS & MACHINE SPECIAL FEATURES

FIBER LASER CUTTER DETAILS & MACHINE SPECIAL FEATURES:

LASER SOURCE: IPG, or Raycus 1000w to 4000w Fiber Laser Source.

WORKING AREA: 10 x 5' ft. Full Sheet capacity

RAYTOOLS (Swiss Brand) DYNAMIC AUTOFOCUS SYSTEM: Sometimes metal sheets are not completely flat. Our “Auto Focus” system is highly efficient and regulates the focus length controlled by a sensor on the laser head automatically. This sensor detects the gap between the nozzle and the material surface at all times. As the cutting process begins the sensor will track the contour of the metal and adjust the nozzle in the z-axis keeping a constant focus point assuring clean and polished edges.

YASKAWA (Japanese Brand) SERVO MOTOR SYSTEM: High precision, detailed capacity, and speed are key elements to obtain the best quality when laser cutting, this is why Flex Laser incorporates Japanese Mitsubishi or Yaskawa servo motors on the steel X and Y axis as well as digitally controlled Drivers. Servo technology is known for its high precision, smooth movements, and ability to operate without cogging at a high speed.

RACK & PINION AXIS FROM TAIWAN: It is a safe and fast movement system that delivers high precision and easy maintenance. Known as “Rack & Pinion”, this system travels smoothly on the gears at high speed reducing to “0” the chances for the machine to get out of phase. It is made with strict manufacturing processes that guarantee maximum stability with minimum wear and tear.

SAFETY FEATURES SUCH AS DOOR SENSORS, EMERGENCY STOP BUTTON: Door sensors to stop the laser beam automatically. Our laser machines are equipped with security sensors and safety features disabling the equipment in case of inappropriate use or unsafe operational conditions. Emergency Stop Button gives the machine operator the ability to IMMEDIATELY and completely shut down the entire machine in case of a problem or any event. The safety turn-on Key feature prevents unauthorized use or operation of the laser machine, allowing only approved operators and/or trained personnel responsible for the operation and maintenance of the equipment.

PC, SOFTWARE, AND INTERFACE: Cypcut Last Version Included. Through a delicate and algorithmic own adaptation, our software uses Bezier's algorithmic curve to help to delineate vector edges in motion, while the speed increases it gets better curving within the range that is working. This algorithm can also avoid incineration or " burning" of material during the cutting process allowing to have a smoother finish on the cut pieces. This software is compatible with a large variety of design programs (Such as Corel Draw. Illustrator, Photoshop, Autocad, and more).

SUPPORTED FORMATS: Supports almost all the design and picture formats such as, bmp, gif, jpg, ai, oux, cut, dsb, dst, dxf, emd, nc, out, plt, smc and more.

AUTO COLLIMATOR " FOR AUTOMATIC CALIBRATION: Our machine incorporates a self-calibration system that reduces setup times and maintenance. Aligns the laser beam precisely.

ELECTRONIC WATER CHILLER UNIT (Included): The electronic water chiller helps to regulate the laser tube temperature while in operation by keeping the water at room temperature. This is a highly efficient unit that requires minimum maintains.

FUME EXTRACTION SYSTEM (Included): Various materials release small amounts of fumes and gases in the engraving or cutting process. To extract these fumes and gases, our Flex Laser comes equipped with an exhaust system and 12 feet (4 meters) of flexible ventilation duct tubing to be installed when the machine is being operated inside a small and enclosed area.

OXYGEN-NITROGEN-AIR VALVE: This system features oxygen, nitrogen, and air valves to regulate the gas flow, a filtration system that prevents water and dirt molecules to reach the lens, a smart air/oxygen flow system, that allows you to control when the gas comes out and an oxygen pressure indicator to make sure you are getting the right pressure you need to keep the best quality when cutting metal.

MANUALS AND INSTRUCTIONAL VIDEOS: An Installation, Operation, and Maintenance Manuals and instructional videos that contains clear explanations of the Installation process and the usage of the software, the control panel, and other features. (For machines only).

30 DAYS HASSLE FREE RETURN POLICY - CLICK HERE FOR DETAILS

Call Us: FL (407) 851 5525 / CA (626) 855 4515.

MATERIALS

FREE Samples With Your Material

With the CAMFive Laser cutter and engraver you can create and produce unlimited projects in a wide range of industries such as sign and displays making, customization of promotional items, party supplies and fundraisings, die cutting, trophies and awards engraving, rhinestone templates, embroidery applications cutting, cutting and etching on fabric, leather and other textiles, tags and label marking, wood and acrylic cutting and etching, among others. CAMFive Laser Cutting, Engraving, Marking and Etching Machine is your best choice.

LASERABLE MATERIALS (CO2 & FIBER TECHNOLOGIES HAVE DIFFERENT CAPACITIES)

| MATERIALS | CUT | ENGRAVE |

|---|---|---|

| PAPER | ||

| CARDBOARD | ||

| PRESSBOARD | ||

| FOAM BOARD | ||

| CORK | ||

| MATTE BOARD | ||

| MDF (PRESSED CARDBOARD) | ||

| TEMPRERED HARDBOARD | ||

| PLYWOOD (PRESSED WOOD) | ||

| WOOD VENEER | ||

| WOOD | ||

| FABRIC, DENIM | ||

| FEET, TACKLETWILL | ||

| COTTON FABRIC AND MIXED DIBERS | ||

| FABRIC WITH THICK SYNTETIC FIBRES | ||

| LYCRA AND OTHER SYNTGETC HETIC FABRICS | ||

| NATURALA AND SYNTHETIC LEATHER | ||

| SUEDE, FLEECE |

| MATERIALS | CUT | ENGRAVE |

|---|---|---|

| MYLER | ||

| PLASTIC | ||

| SILICON WRISTBRANDS DS/BRACELETS | ||

| RUBBER (GUM ELESTIC OT INDIA RUBBER) | ||

| DELRIN | ||

| ACRYLIC | ||

| CORIAN | ||

| MELAMINE | ||

| FIBER GLASS | ||

| GLASS (TEMPERED) AND CRYSTAL | ||

| CRAMICS | ||

| MARBLE, ONIX AND STONES | ||

| TILE | ||

| PAINED METALS | ||

| COATED METALS | ||

| ANODIZED ALUMINIUM | ||

| BARE METALS |

SPECIFICATIONS

FLEX LASER MACHINE TECHNICAL SPECIFICATIONS

Working Area: 10' x 5' ft (3.0 x 1.5 mts).

Work Table Type: Fix

Machine Weight: 7,800 pounds

Machine Dimensions: 214" x 124" x 100"

Control Software: CypCut Last Version (included) for vectors and graphics processing.

Graphics Format Supported: DXF, CAD, PLT, AI, LXD, etc

Working Voltage: 220V (Adding a converter) or 380V - 60 GHz.

Power Consumption: 6 kw to 9KW

Operation Temperature: 5 - 95% Non condensing | 35 ° F- 77 °F

Fully Enclosure

Driving System: Japanese Servo motor and driver

Blower: 2.2kw Industrial grade (Included)

Laser Source: 1000W IPG, Raycus or RECI (Available Upgrade to 1500w, 2000w, 3000w, and 4000w)

Cooling system: Electronic Industrial Chiller (Included)

Lubrication System: Automatic (Included)

WARRANTY

In CAMFive LASER we exceed our compromise with our customers. Our most important goal is to full fill your expectations and needs.

We provide outstanding customer service to satisfy our customer request.

CAMFIVE LASER ALSO OFFERS:

-

COMPLETE INVENTORY OF SPARE PARTS FOR ALL THE LASER ENGRAVER & CUTTER MODELS.

COMPLETE INVENTORY OF SPARE PARTS FOR ALL THE LASER ENGRAVER & CUTTER MODELS. -

SPECIALIZED TECHNICAL SUPPORT.

-

FAST RESPONSE TO OUR CUSTOMER REQUIREMENTS

-

CONTINUOUS IMPROVEMENTS IN OUR SERVICE.

CAMFive LASER offers a comprehensive warranty policy, for more information and complete terms: CLICK HERE